An earlier picture showed the whole finished

motor mount made with slotted bed rails.

Slotted bed rail pieces can work well work well

only if they are welded to heavy angle iron. This

pipe handle was added for more than ease of

speed changing, it really cut down on twisting

of the assembly under load. All the pulley

brackets should have these pipe handles for

this reason! Don't forget that the motor

electrical connection box can get in the way if

plenty of room is not left for it.

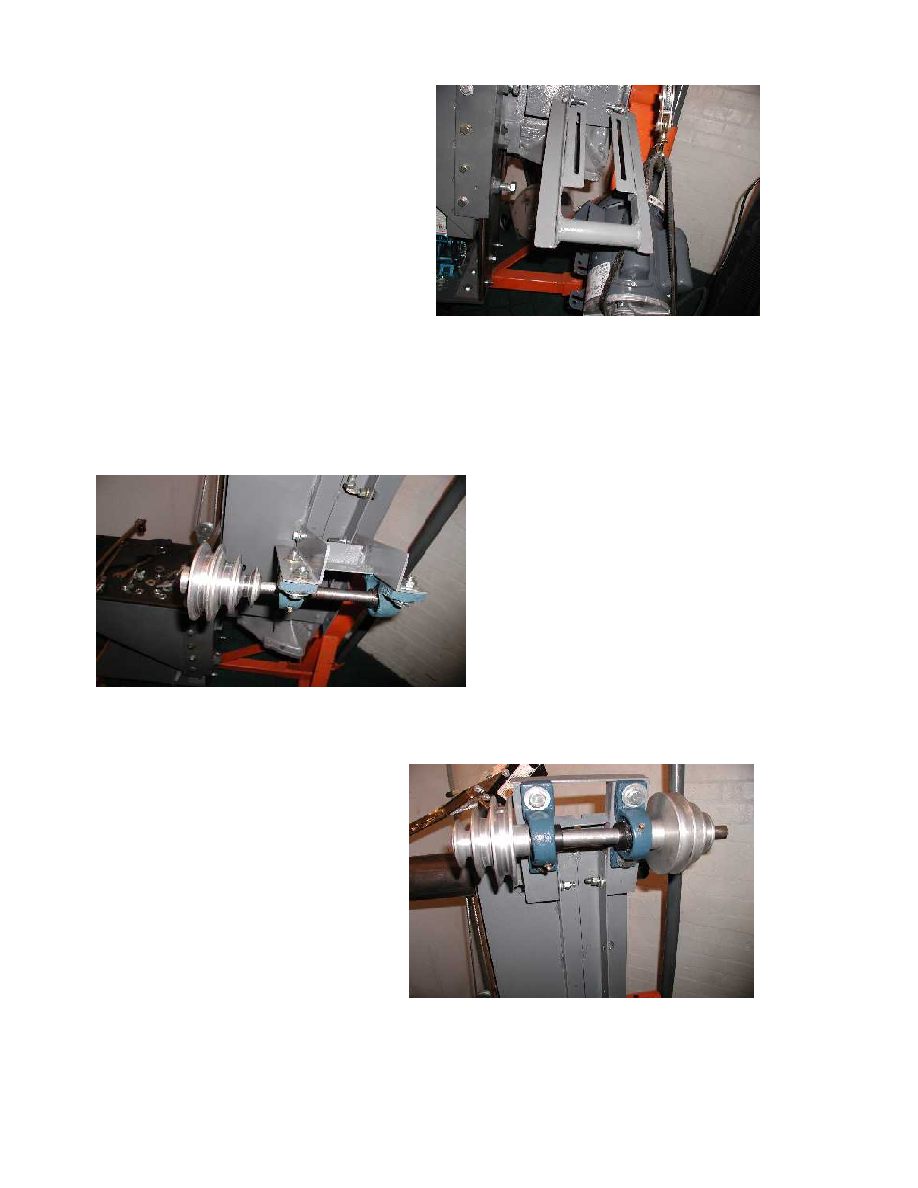

Again, it would be best if the pulleys were mounted inboard the mounting rails if possible.

Be sure to lay everything out first so you can be sure the motor and pulley assemblies all fit

properly. Work carefully here and you will get a quiet, powerful machine that is less likely to

"chatter".

The intermediate pulley bracket.

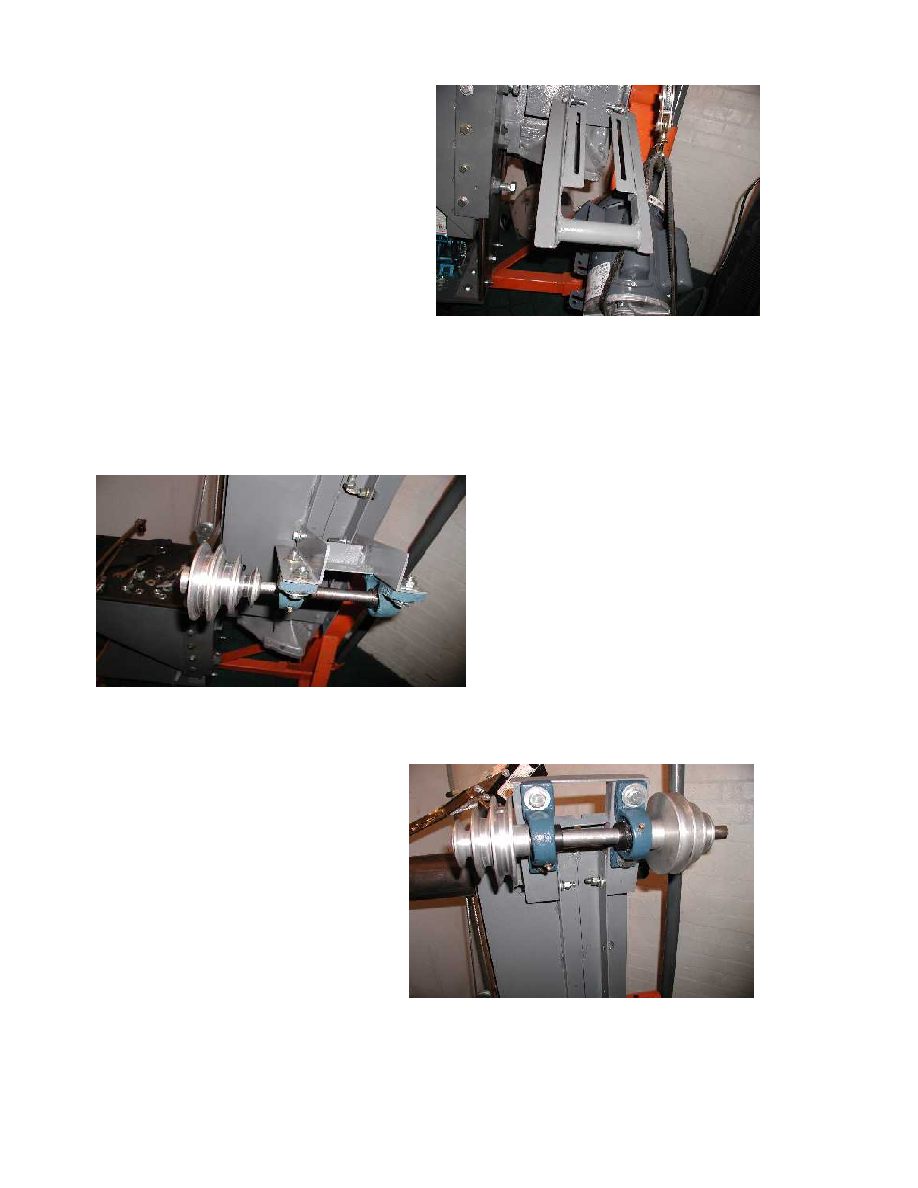

This is what I call the final drive bracket. It

should be made out of one foot long heavy

angle iron and as wide as possible. Add a

pipe handle at the top to make it more rigid

and easier to adjust. I reinforced this one

several times and it still twisted.

Here is the final drive adjuster. Pretty crude but like I said before, I am an inventor not a

32