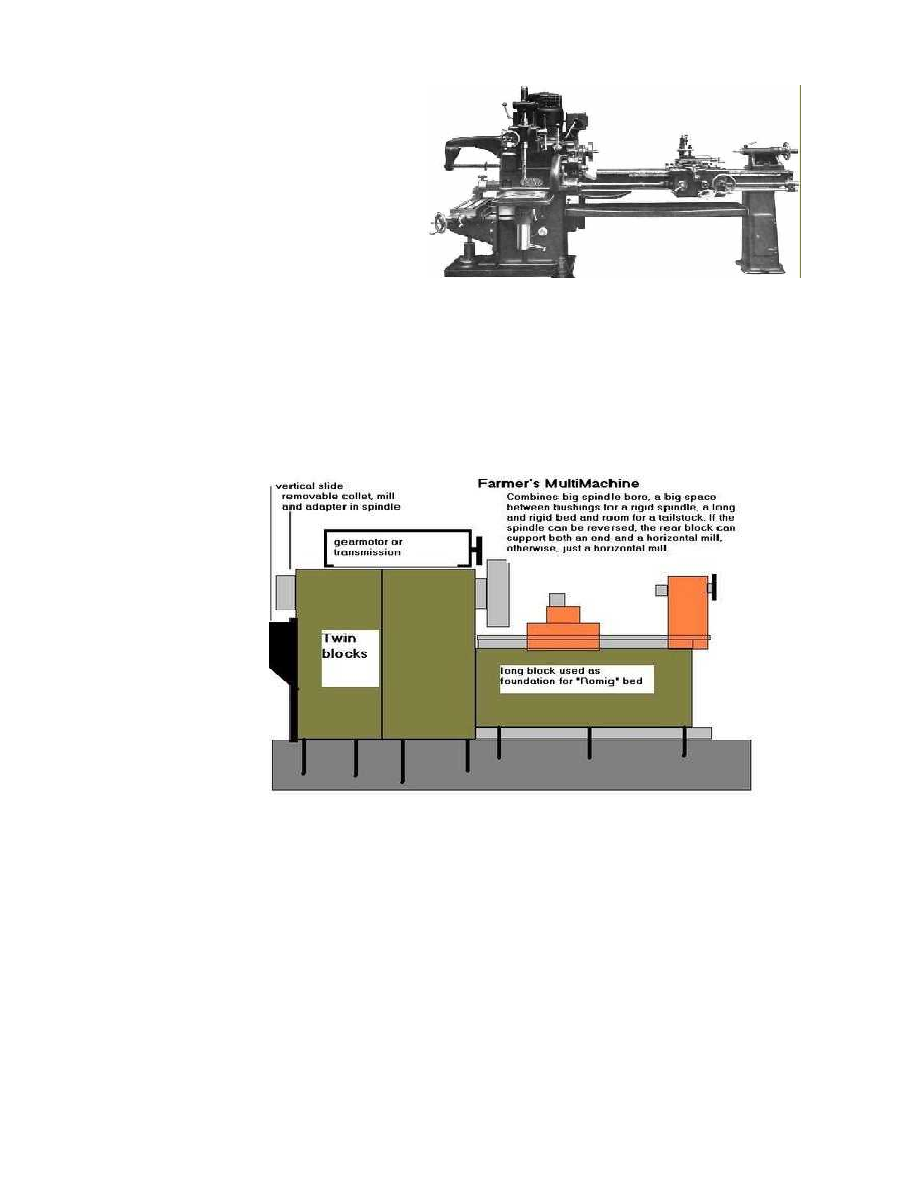

"Double-sided" MultiMachines (lathe on one side, all-function machine on the other) are perfect

candidates for Variable Frequency Drives that make the machine spindles both variable speed

and bi-directional. Pictured below is a four-block version with doubled vertical blocks mounted

back to back so it can support a 4'-long spindle useful with a heavy chuck. The machine can

also have a rear vertical slide, and a 4- or 5-block version with a Bridgeport-like head could have

an added horizontal block with powered spindle added on top.

The most common size for a MultiMachine has 12-to-15" of table vertical travel and a 32" lathe "swing." The

horsepower required for regular lathe-type cutting tools makes them hard to use large work pieces. BUT...If you

replace the cutting tool with a simple $30 bench grinder or even a homemade toolpost grinder, you can machine

really big jobs. You can even resurface large clutch and brake parts for a truck.

By using the simplest metal casting technique, a skill that has been around thousands of years,

you can turn out products using machined aluminum alloy. It then becomes possible to build

things like pump parts and to cast alloy bushings that could replace expensive ball bearings. One

common alloy, ZA-12, contains about 12% aluminum, with zinc as most of the remainder. Both

8