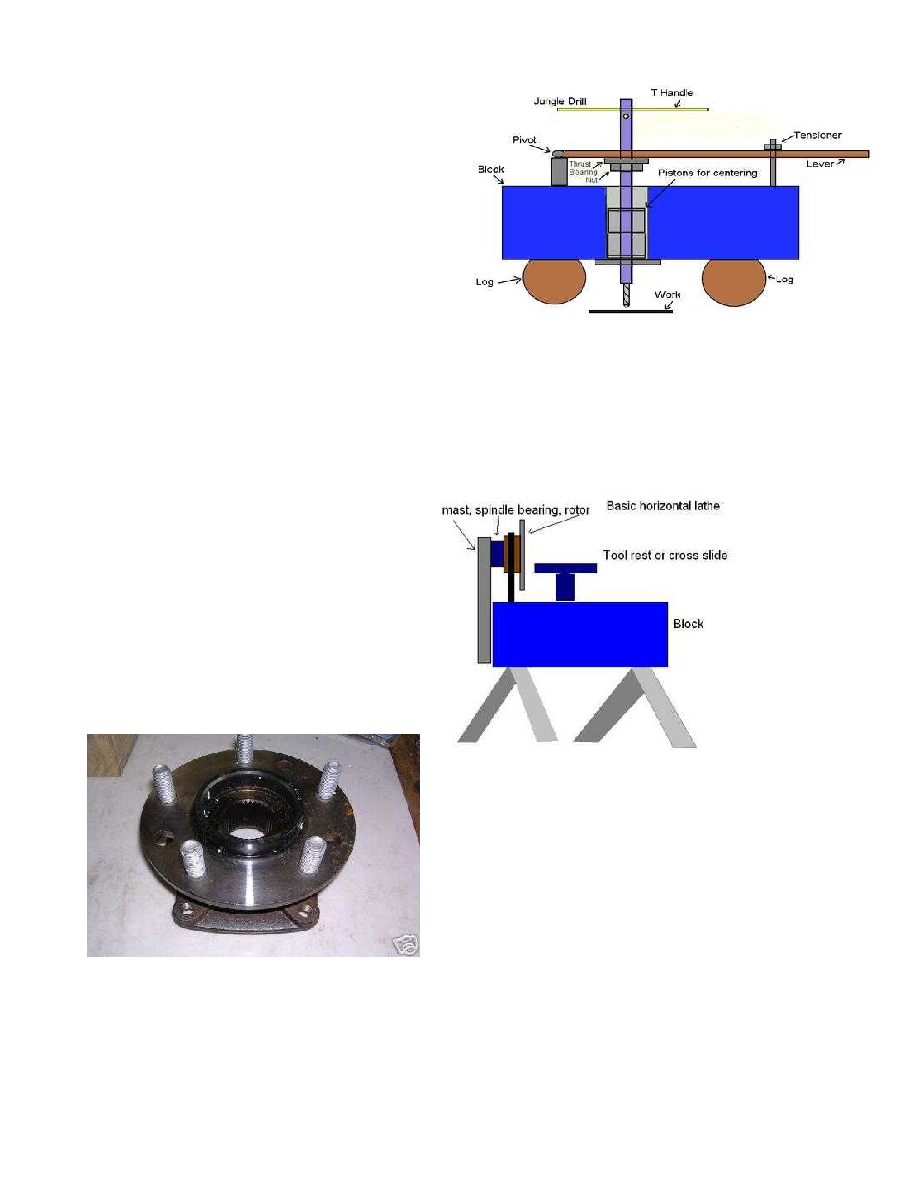

"Cole" type drills may require a very small amount

of welding (total bead length is less than 4") but this

can be done using a simple temporary welder that

can be made by connecting two or three vehicle

batteries in series (negative on one battery to

positive on the next). The drill spindle assembly can

also be made well in advance and the chuck just

screwed on to complete construction.

By mixing and matching the ideas above you have

many ways to drill the holes needed for a

"temporary" lathe and as I said earlier such a lathe will allow you to build almost anything. Why

the "temporary" name for a machine that would be useful for years? I had to call it something at

first and this name just "stuck"

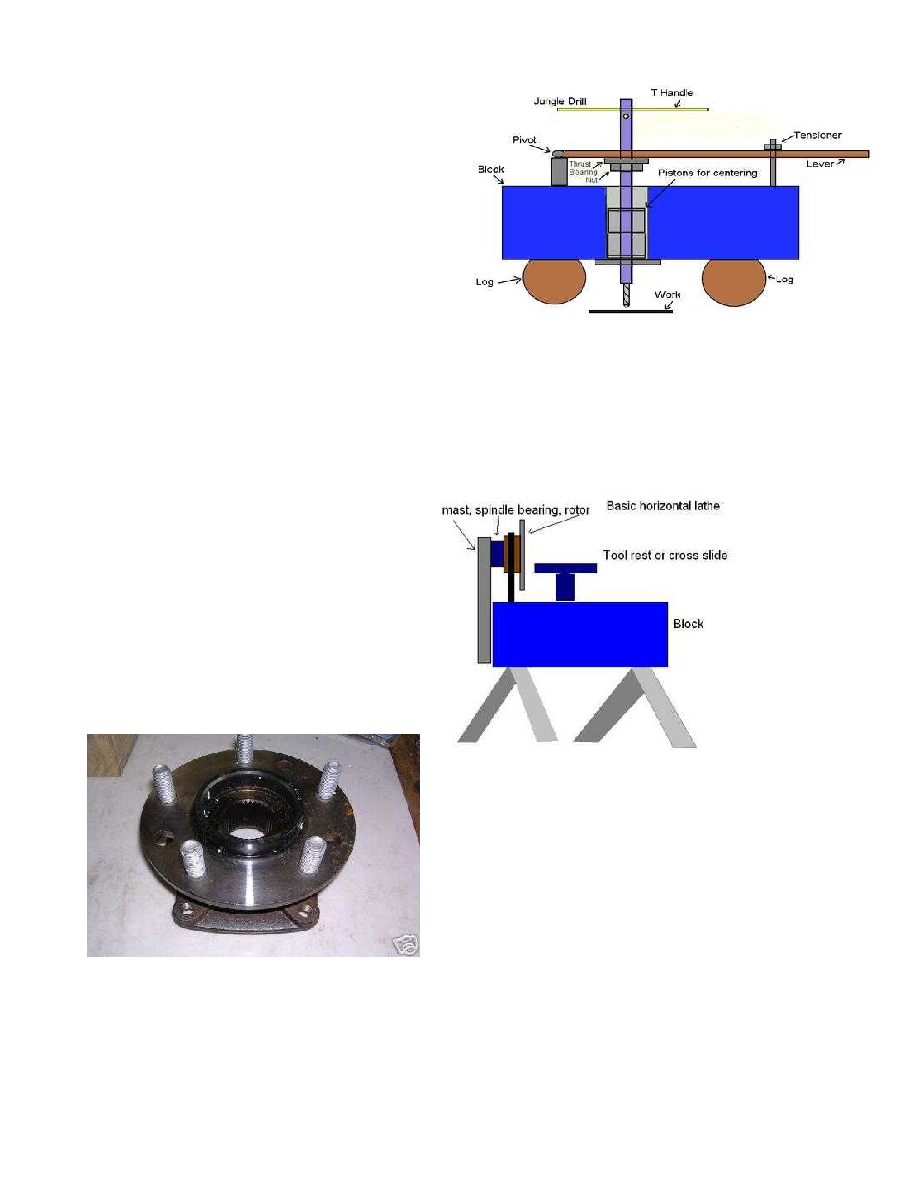

Once you have the drill the next step is to build the "temporary" lathe.

The reason we need the temporary lathe is for

the machining of bushings, spacers, adapters,

pulleys. These machined parts that can easily

be made from zinc and aluminum alloy lets the

builder save most of the money that would be

needed to build a regular MultiMachine. These

easily cast and machined parts make a much

larger machine quite easy and inexpensive

(almost free!) to build. A roller bearing with a

5.5"ID could cost thousands of dollars while

one made from homemade alloys could cost

almost nothing.

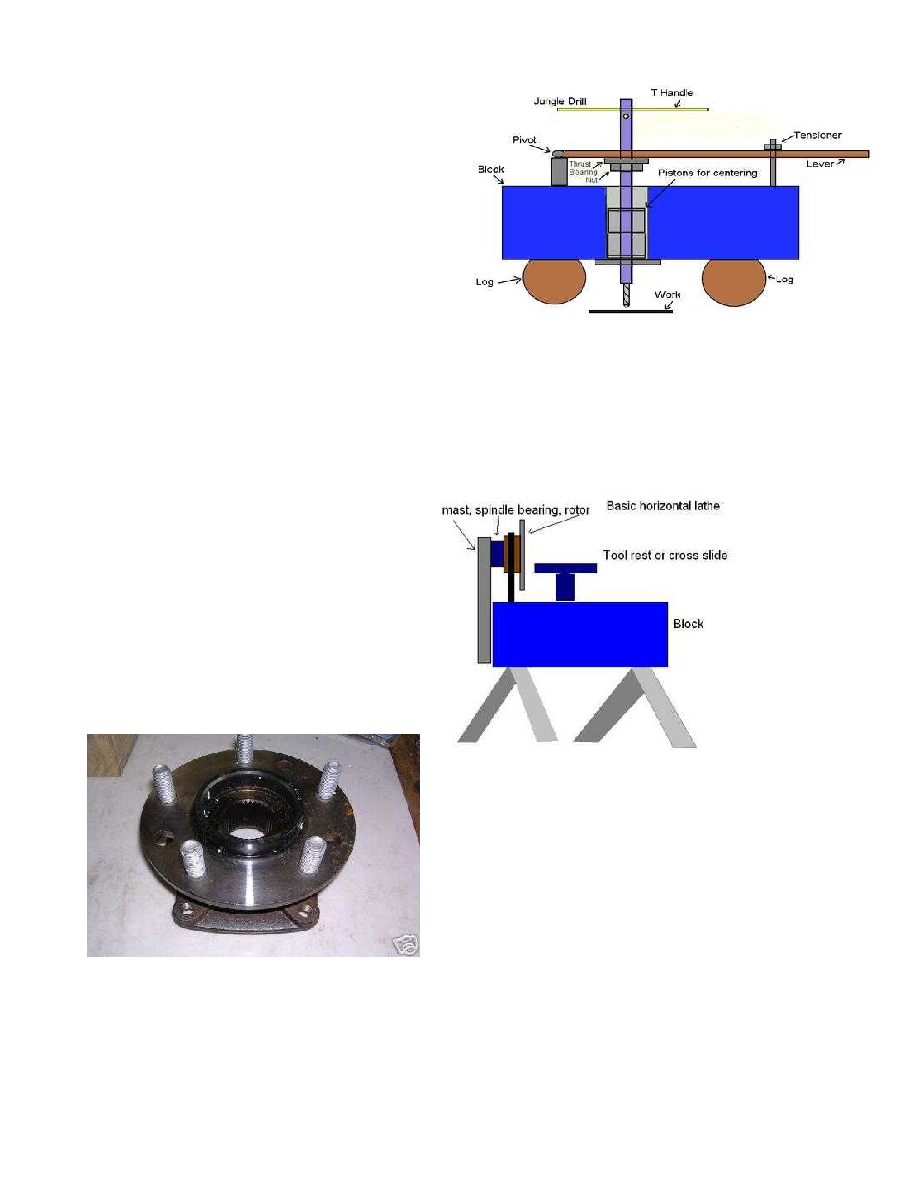

A really simple "temporary" lathe, use a hub from

a front wheel drive car. The cutting tool can be as simple as a large allen wrench (good steel)

ground to the proper shape and attached to a long handle. Blacksmiths used this technique on

iron and steel for many years and using it on zinc/aluminum alloy will be much easier. This is

another very good reason to learn the basics of tool grinding.

56