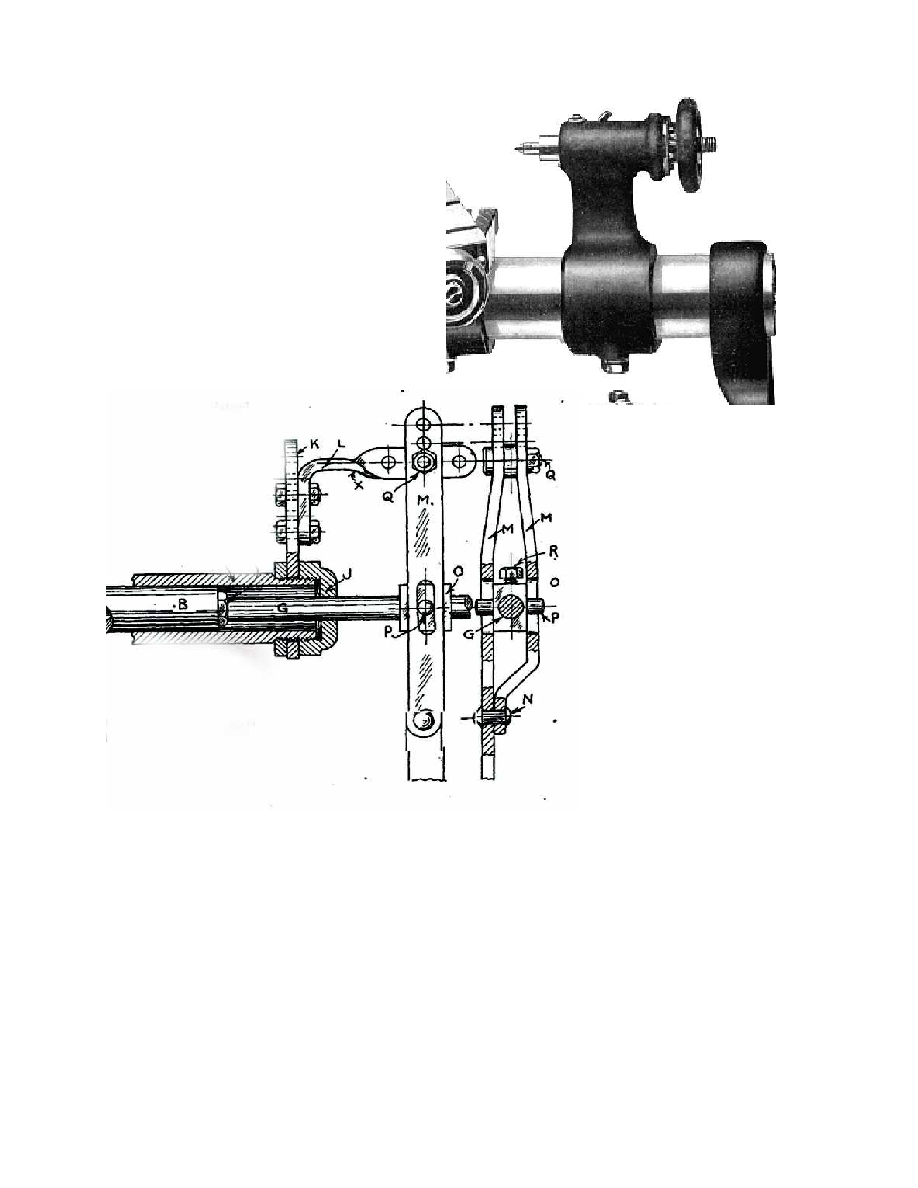

This photo is of an old Drummond round bed

lathe tail stock. If it were turned up side down, it

would be a great design for a MultiMachine. It

was kept in alignment with a "V" shaped key on

the bottom of the round bed.

Casting one like this out of ZA-12 would be

great.

If you build a "Romig" type bed then add a

conventional lathe type tailstock to it. It could

be similar to this but would need a flat bottom

that would match the "Romig" bed.

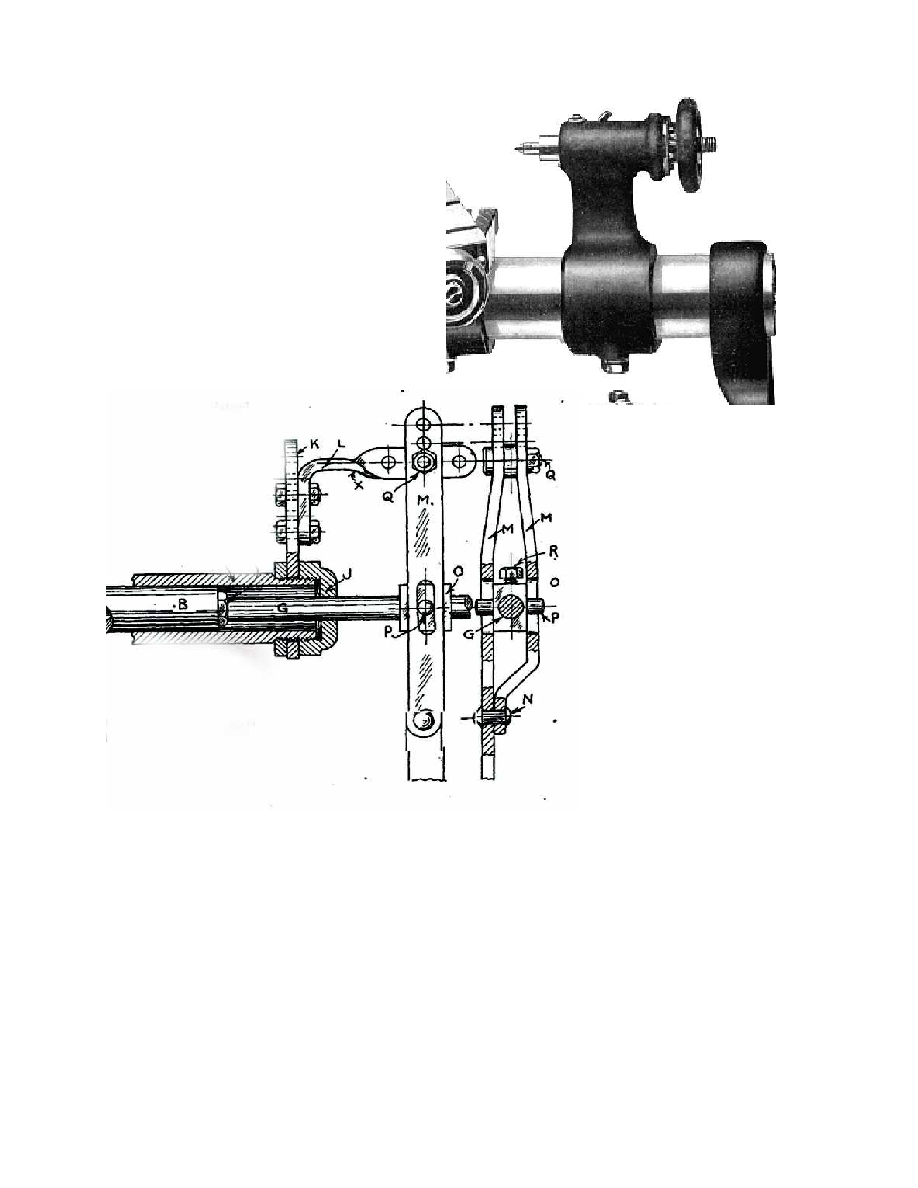

A great lever tailstock that was designed to speed up production in WW 2.

The next few pages cover three tools/techniques that will complete

your MultiMachine.

(1) A "broken bit" cutting tool system that can save hundreds of dollars in tool expense.

Even though the included pictures show only round bits, the bits can be ground into

conventional cutting tool shapes.

(2) An accurate homemade lathe chuck.

(3) A very old but accurate way of cutting threads. The MultiMachine Yahoo newsgroup

will have plans for a CNC lead screw when one becomes available.

50