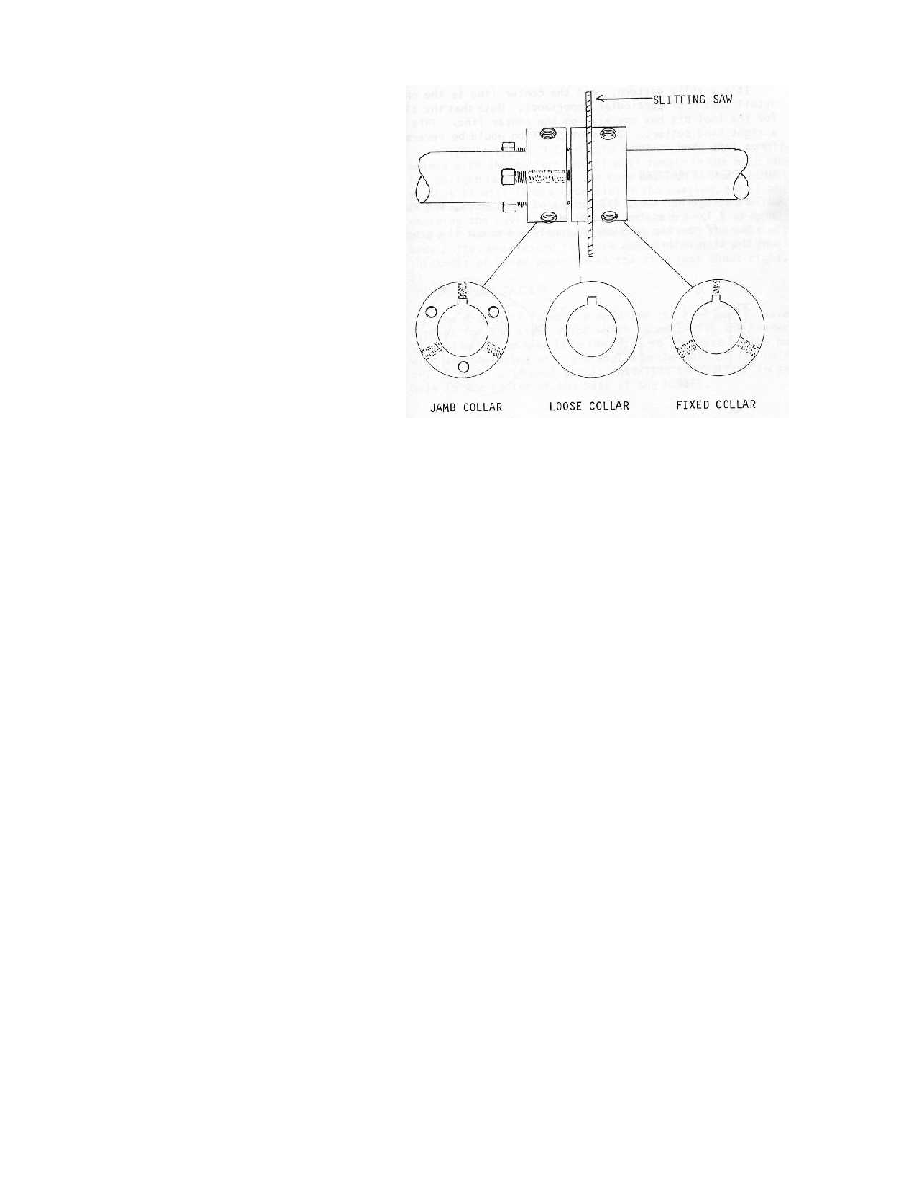

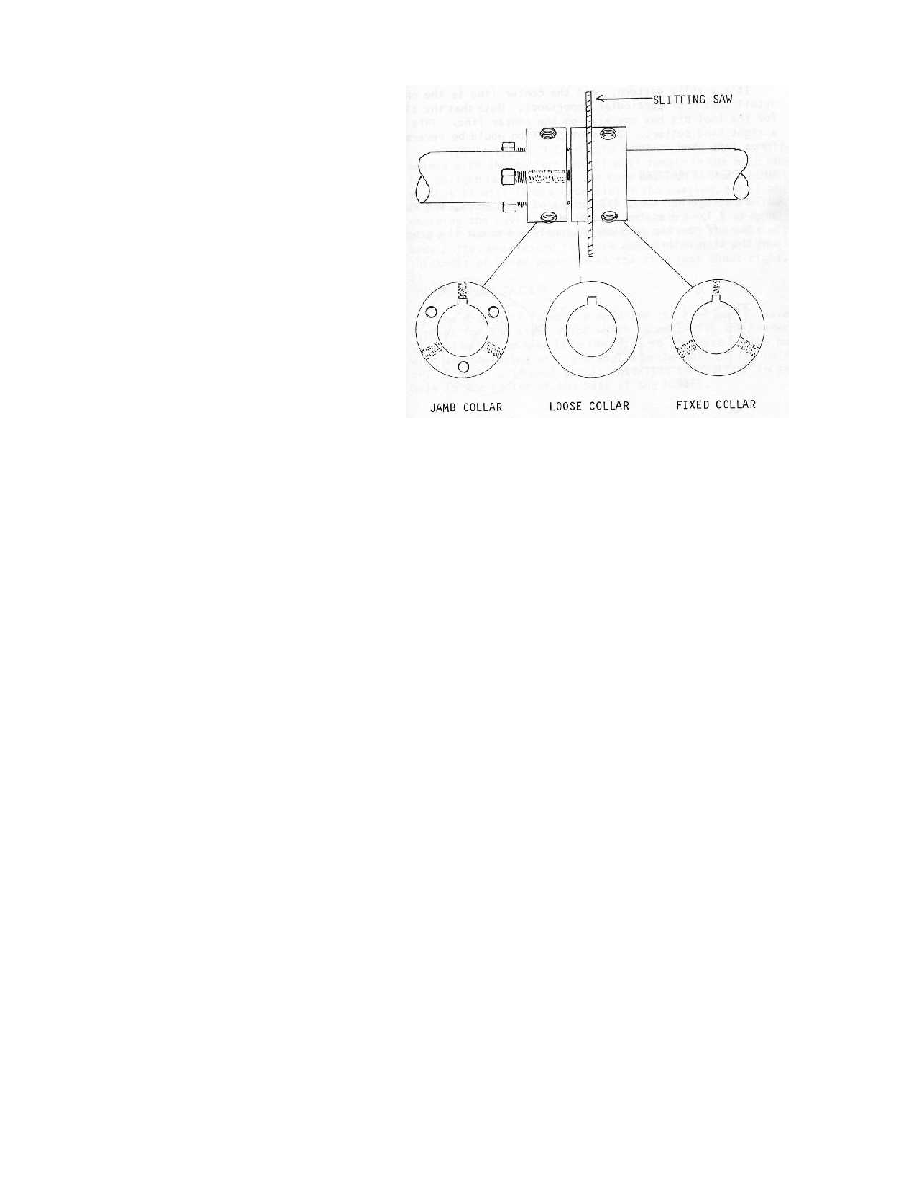

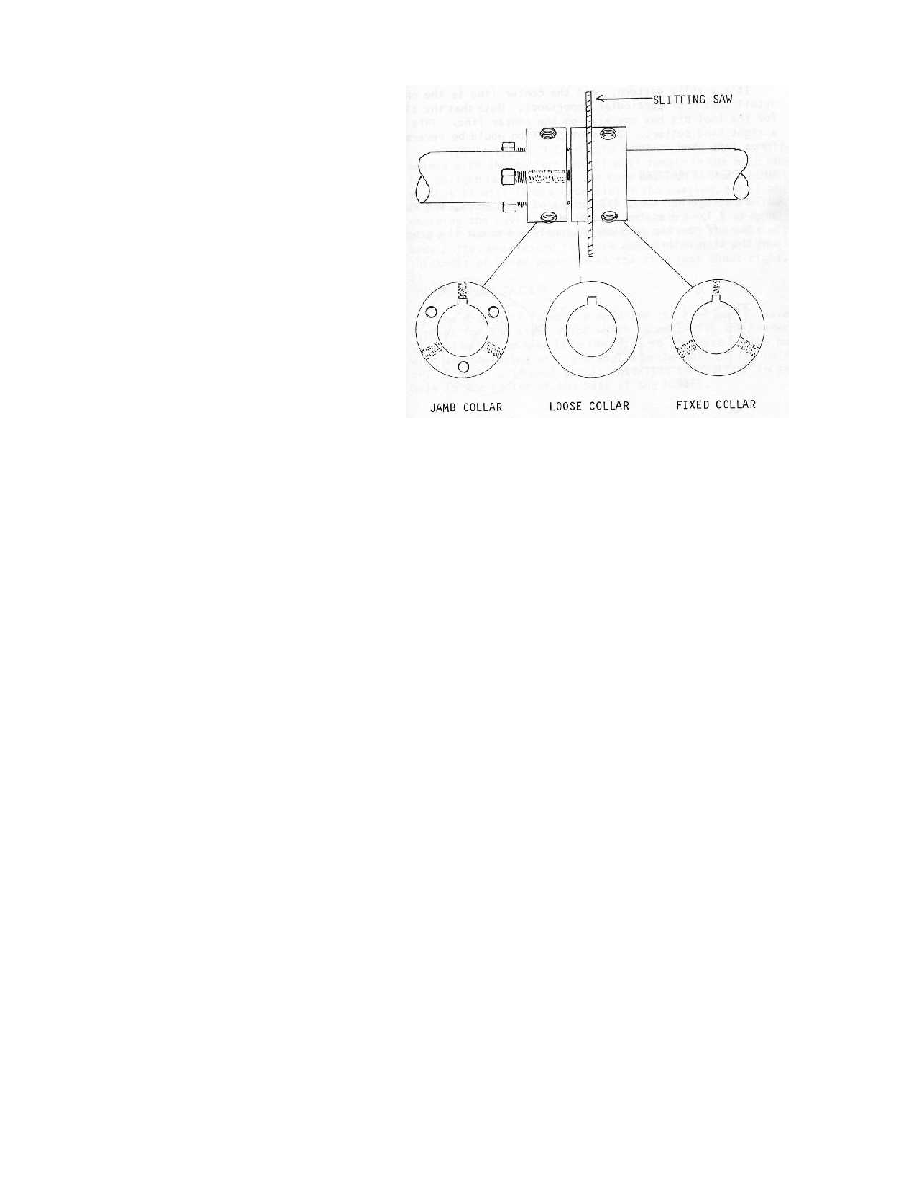

The Gingery horizontal mill arbor. I

would replace the three setscrews that

position the fixed collars with just one

setscrew and a clamp bolt (or bolts) like the

horizontal mill cutter.

If you don't already own the Gingery

casting and cast machine tool books, buy

them! Combining the power of the

MultiMachine with skills that you learn

from building the Gingery tools will let you

build almost anything!

I mentioned the third bearing earlier. It locates the whole spindle assembly. It serves as a thrust

bearing which is necessary with the roller bearing spindle because these bearings just "float" in

the cylinder bore and it also supports the drive pulley. This pulley may weigh 20 to 30 pounds

and be 10" out from the inner roller bearing so additional support is vital. Three bearing

spindles are unusual because of possible alignment problems, we will cover our easy solution to

this a little farther along. The thrust bearing/bushing can be as simple as a cast sleeve with a

shoulder that would bolt to the main bearing pads and two thin versions of our "adjusters"

clamped to the spindle.

Now... something I consider very important. Everybody will want to put his own "stamp"

on his machine. Think carefully before you do it here. The spindle MUST be centered on

the cylinder bore because this lets you align the lathe bed or cross slide with the block

cylinder head surface. Trying to align machine parts by using the short piece of spindle

that sticks out from the main block is almost impossible. Think carefully before you

change something here. Think ease of re-alignment FIRST! The table can go up and down

16" or more and the cross feed may be able to rotate 360 degrees but all this will be wasted

if the table and cross slide has to stay locked in place because they are simply too hard to

re-align!

Another extraneous but very important thought!

The size and weight of the MultiMachine really do matter! In the late 1800's the vertical slide

alone on a similar capacity horizontal milling machine commonly weighed 3000 lbs. In the early

1900's Cincinnati, the great American milling machine company increased the weight of their

machine bases by over 600% when they found that under heavy cuts the cast iron bases were

flexing like drum heads. Today 2 or 3hp Bridgeport milling machines weigh over 2400 pounds

for a good reason. Your MultiMachine may weigh only a third of this so always keep in mind the

importance of using sheer mass to suppress vibration.. Concrete is your friend, when you get

your machine to work like it should then fill the base of the main block and also the vertical slide

with polymer concrete mix.

21