A little extra work lets you save a lot of money! I'm assuming that you would like to spend as

little money as possible on this project. If you can afford to spend a lot, just search eBay and

Craig's List for some of those wonderful machines left behind when US jobs went to China.

When I built my MultiMachine, I tried to find ways to build it that could take almost no money

and little or no electrical power either for building or operating it. I wanted a machine that could

be built and run anywhere in the world outdoors, in a shed without power, or in the finest

workshop. The result is a machine that could be grouped with others like it to make a small

factory. The machines could be powered by a single gas or diesel engine running an overhead

shaft that is connected to them by simple pulleys and belts.

You may have to learn a few new skills to build the machine, but these skills are also

needed to make best use of the MultiMachine.

Two important skills covered in many old machining books are grinding cutting tools to the

correct shape and clamping work on a lathe faceplate. These kinds of subjects are also usually

covered in just 20 or 30 pages in almost any of the older machining books that can be found in

your local library, In our MultiMachine newsgroup or elsewhere on the web.

The shape of the cutting tool is important in every lathe, milling and shaping/slotting machine

operation. The tool has the same basic shape for many of these different operations. Learning the

basics of grinding metal-cutting tools to the proper shape will save you lots of money.

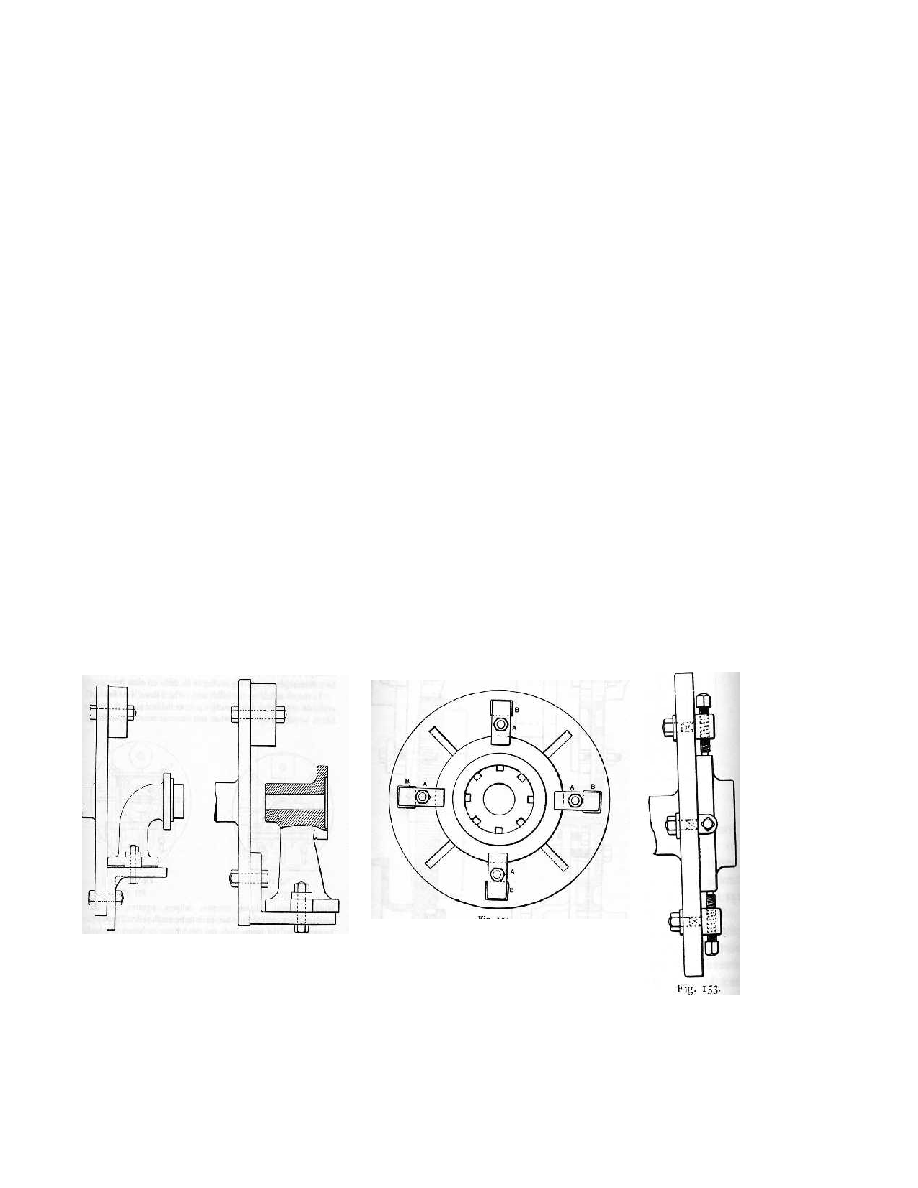

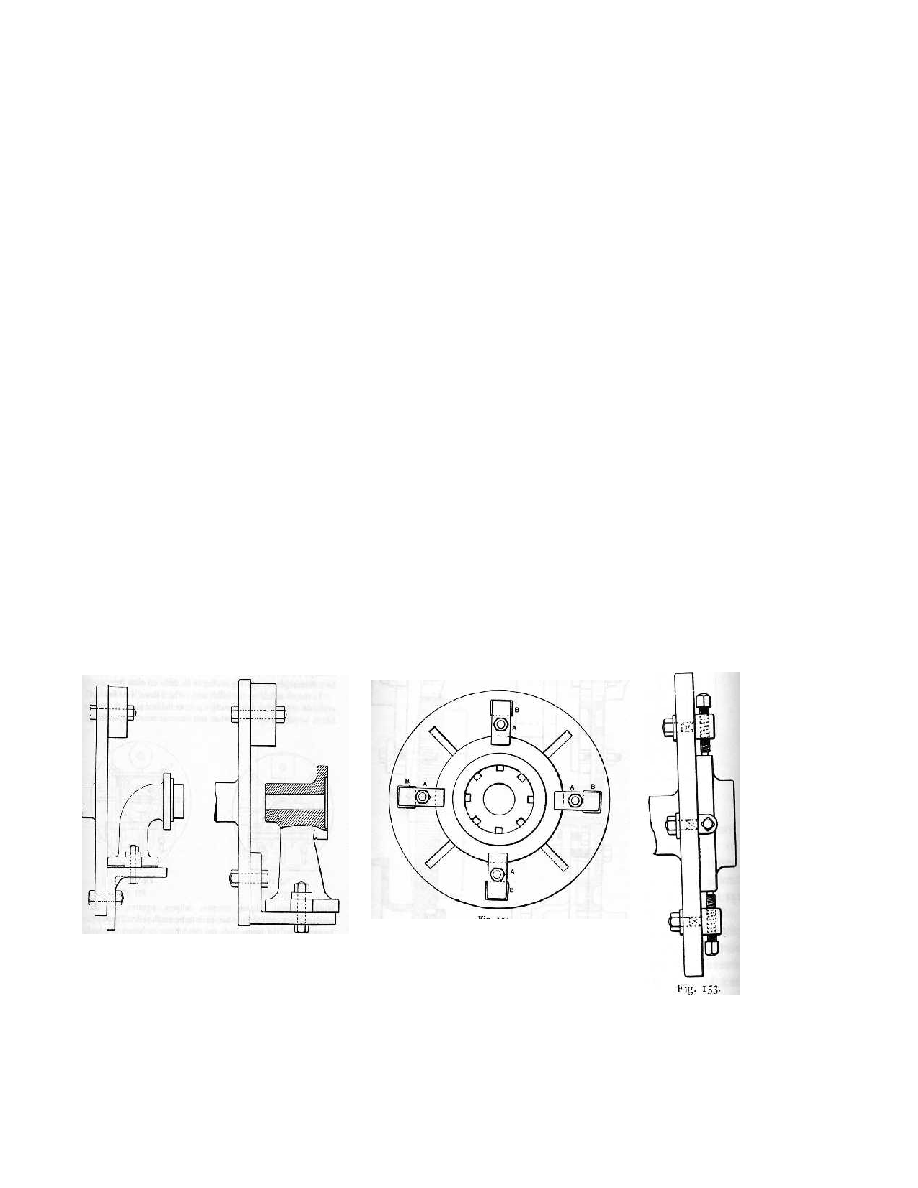

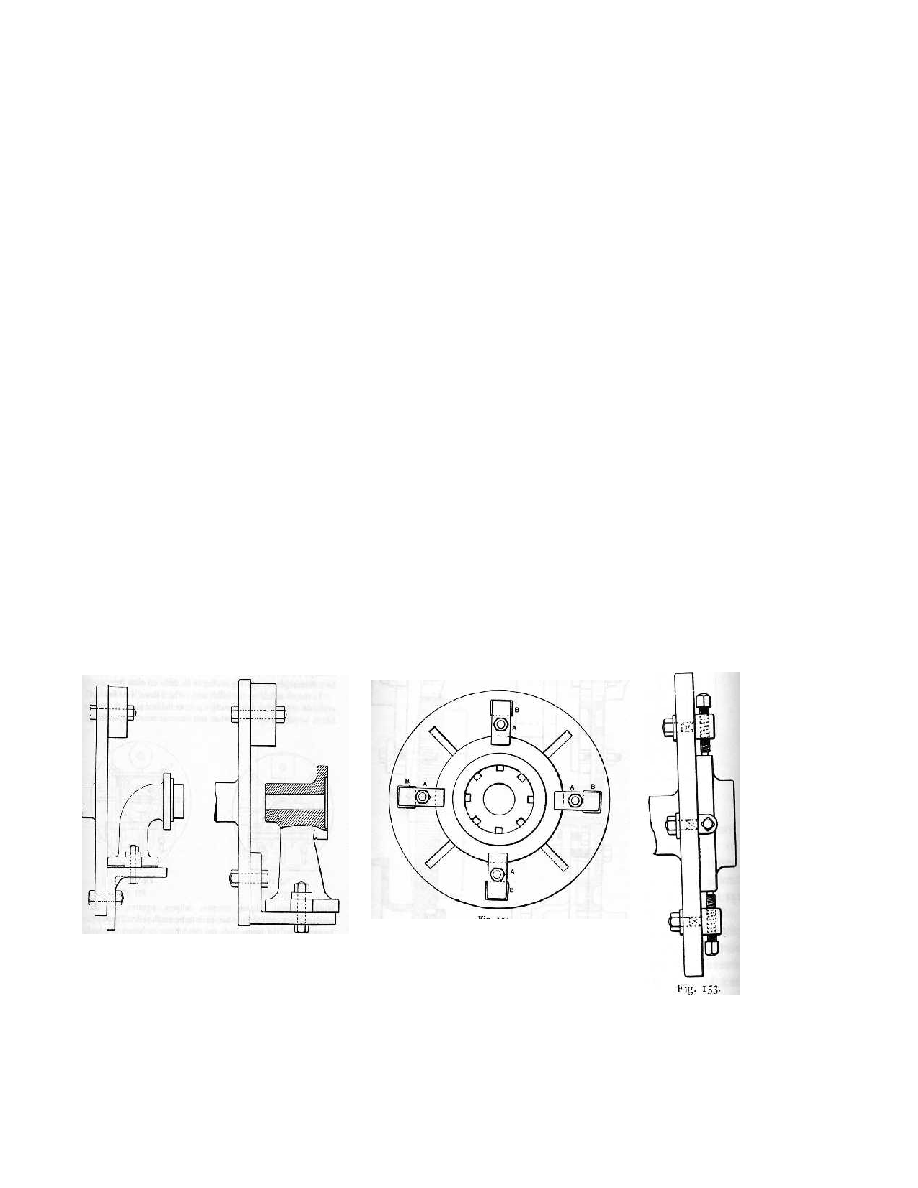

How to clamp work to a lathe faceplate is the other basic machining skill needed. There are

many ways to do this that are described in older books. (See samples below.) Since three- and

four-jaw chucks were not common for the first 80 or 90 years of wide metal-lathe usage, metal

workers did without them. So can you if you have to.

14